Sidel Filling Line for Still Water

Latest Machines

Sidel Filling Line for Still Water

or

Call +44 (0) 133 232 2578

Description

The Sidel FM 100 is a filling line specifically designed for still water, offering automated solutions for high-efficiency bottling. Here are some key features and benefits:

- Flexibility: The FM 100 can handle various bottle sizes and shapes, making it adaptable for different products and market needs.

- Efficiency: The filling technology minimizes product waste and ensures a consistent fill volume, which is essential for quality control.

- Automated Processes: The line incorporates automated processes for bottle handling, rinsing, filling, capping, and labeling, resulting in a streamlined production line and reduced labor costs.

- Sanitization: The FM 100 is designed with hygiene in mind, featuring materials and designs that facilitate cleaning and sanitization, which is critical for food and beverage applications.

- Speed: The line is capable of handling high throughput, allowing for efficient production schedules that can meet increasing market demands.

- Energy Efficiency: The equipment is built with energy-saving technologies that reduce overall production costs while maintaining performance.

- User-Friendly Interface: Operators benefit from an intuitive control system that simplifies monitoring and adjustments during operation.

Choosing a used Sidel line for still water filling can offer several advantages:

- Cost Efficiency: A used Sidel line is typically more affordable than new equipment, resulting in significant savings for your production setup.

- Proven Technology: Sidel is a well-known brand in the beverage packaging industry, recognized for their reliability and advanced technology. A used line still maintains the quality and efficiency of Sidel's systems.

- Quick Implementation: Purchasing a used line can expedite your acquisition process, allowing you to start production sooner compared to waiting for a new system to be manufactured and installed.

- Lower Depreciation: Since the equipment is already used, it has already undergone significant depreciation, which means you might recover your investment more quickly.

- Availability of Parts and Support: Sidel has an extensive service network and parts supply, making it easier to maintain and service used equipment.

- Flexibility: A used line can often be customized or upgraded to meet your specific production needs, providing flexibility in your operations.

- Sustainability: Opting for used machinery can be seen as a more sustainable choice, as it extends the lifespan of existing equipment rather than contributing to the production of new units.

- Established Performance: With a used line, you have available performance data and history, allowing you to make informed decisions about reliability and efficiency based on real-world usage.

Specifications

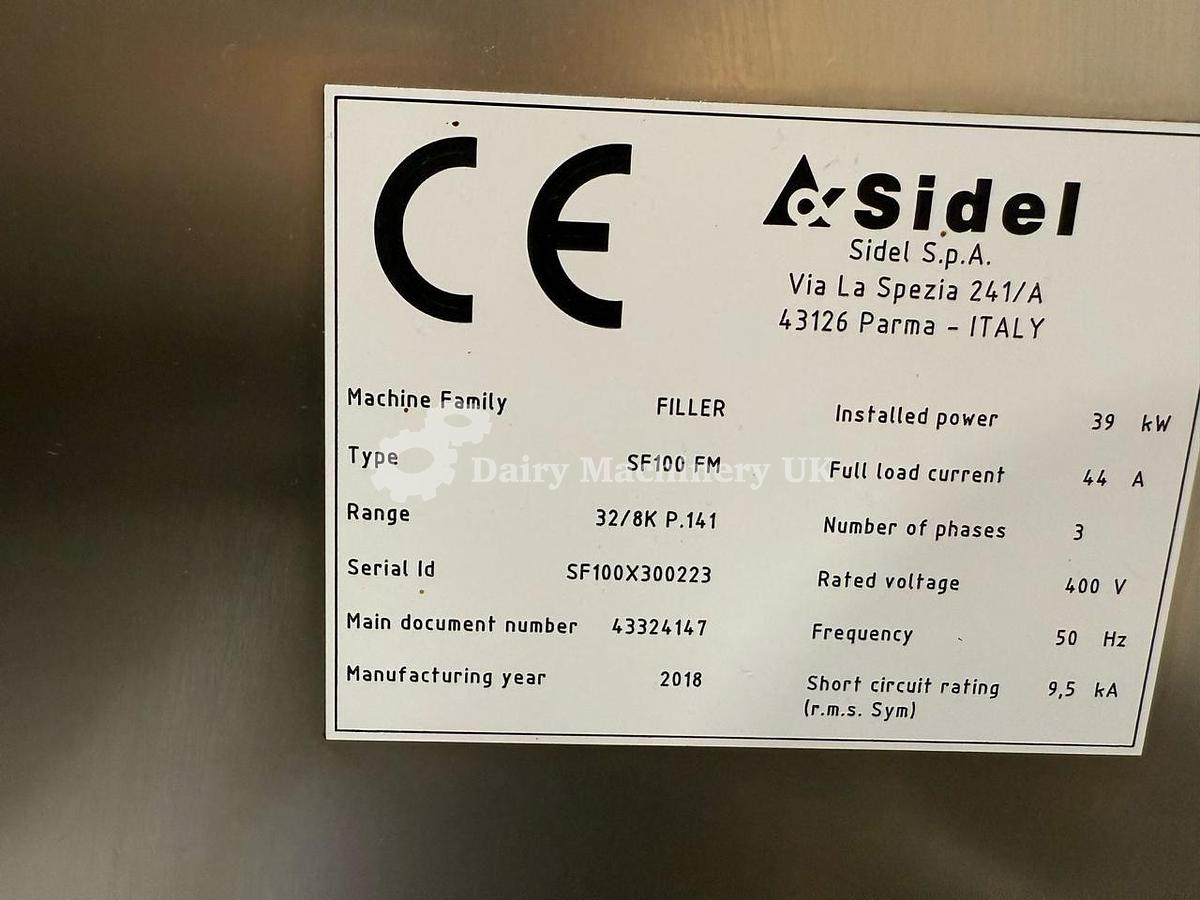

| Manufacturer | Sidel |

| Model | SF100FM |

| Year | 2018 |

| Condition | Used |

| Serial Number | SF100X300223 |

| Stock Number | 823 |

| Filling Machine | Sidel SF 100 FM |

| Cap Size | 28 mm |

| Filling volumes | 500 ml - 1 Litre and 1,5 Litres |

| Blow moulder Type | Sidel |

| Blow moulder model | Matrix |

| Moulds | 500-1000-1500 ml round Bottles |

| Pre forms Hopper Feeder Make | Sameto |

| Pre Forms Feeder Type | EBHIS 205 |

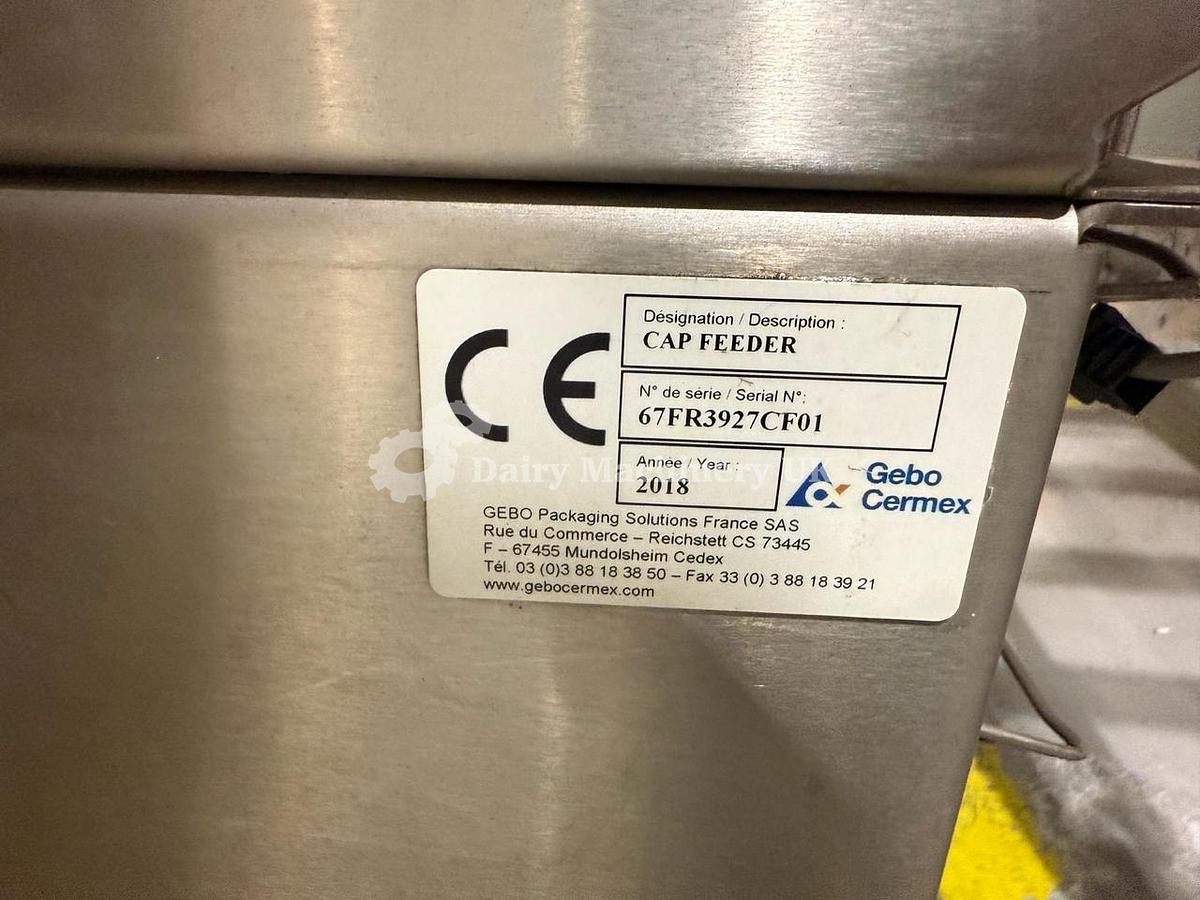

| Cap Feeder | Tetra Pak / Gebo Cermex |

| Cap Feeder Serial Number | 67FR3927CF01 |

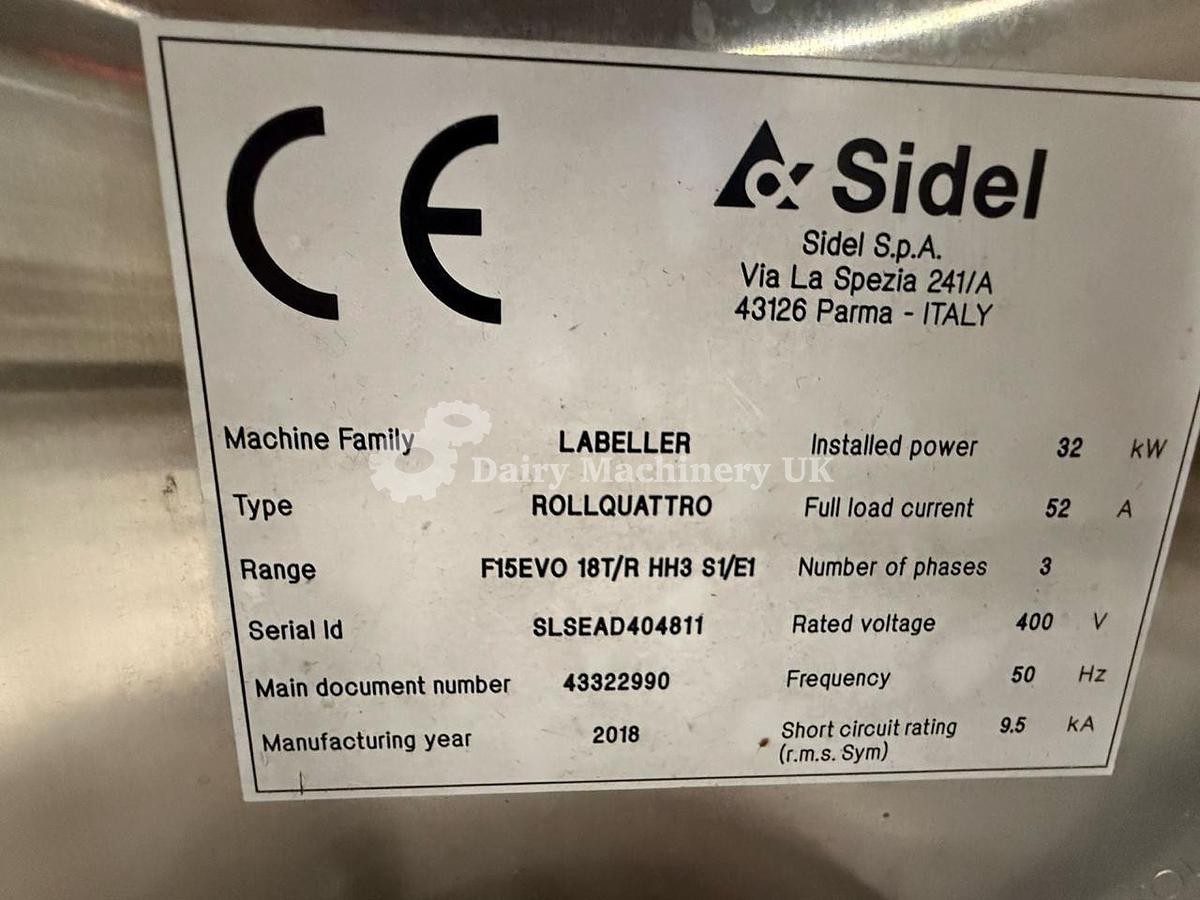

| Labeller Make | Sidel |

| Labeller Model | ROLLQUATTRO |

| Labeller Serial Number | SLSEAD404811 |

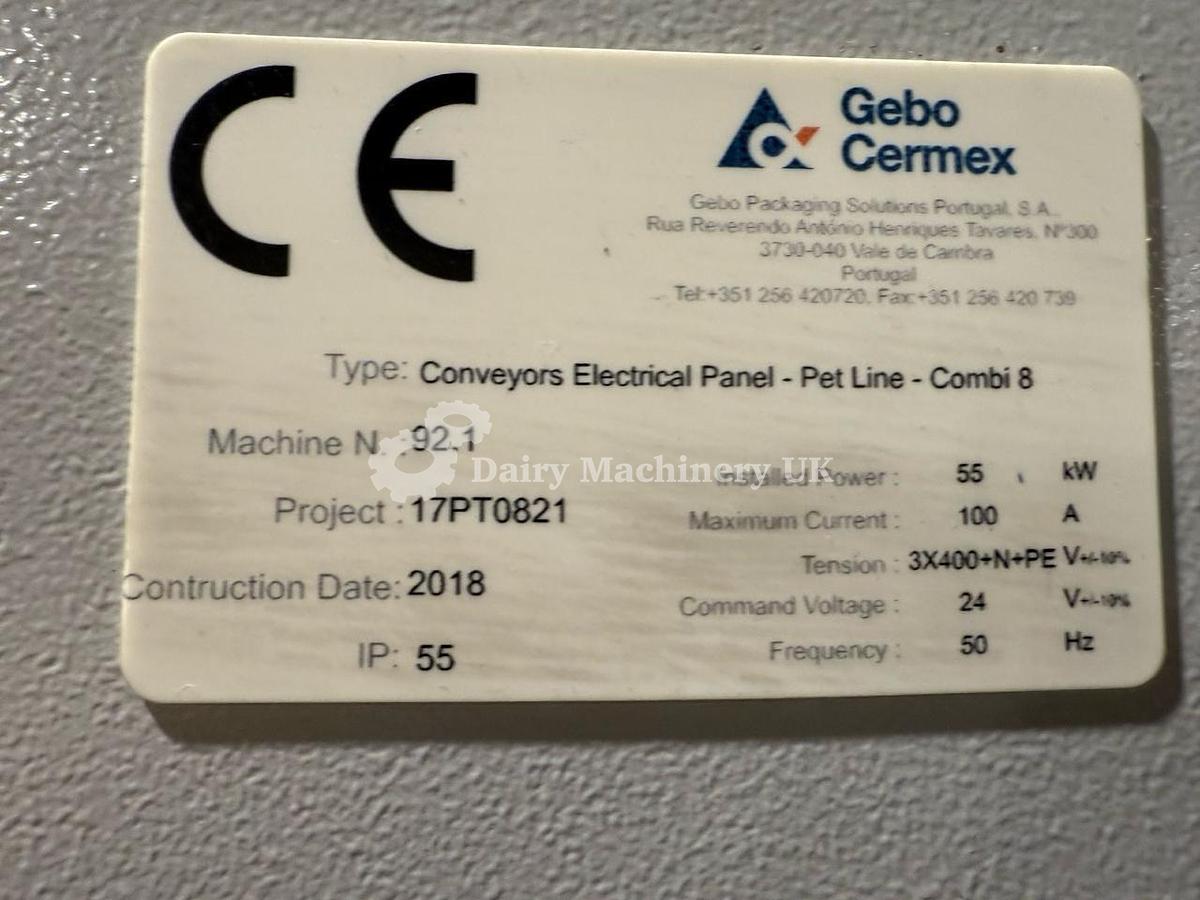

| Conveyors Make | Tetra Pak / Gebo Cermex |

| Shrink Wrapper Make | Sidel |

| Shrink Wrapper Model | Versa Film Access |

| Handle Appicator Make | Kartville |

| Palletiser Make | Tetra Pak Gebo Cermex |

| Palletiser Serial Number | GIBP1055 |

| Palletiser Model | KOMBI |

| Robot Stacker | ROBOPAC |

| Robot Stacker Model | HELIX 3 E |